The team of scientists who created the smallest magazine cover. (Left to right) Simon Bonanni, scientist at SwissLitho, and from IBM, Michal Zientek, Armin Knoll and Colin Rawlings

In preparation for the latest edition of the Guinness World Records, tech giant IBM has taken small-scale publishing to a whole new level by designing a magazine cover 2,000 times smaller than a grain of salt.

The IBM scientists were able to create this minuscule publication by inventing a tiny 3D printing ‘chisel’ with a heatable silicon tip 100,000 times smaller than a sharpened pencil point.

Using this nano-sized tip, which creates patterns and structures on a microscopic scale, it took the IBM scientists just 10 minutes and 40 seconds to etch the magazine cover onto a polymer, the same substance of which plastics are made.

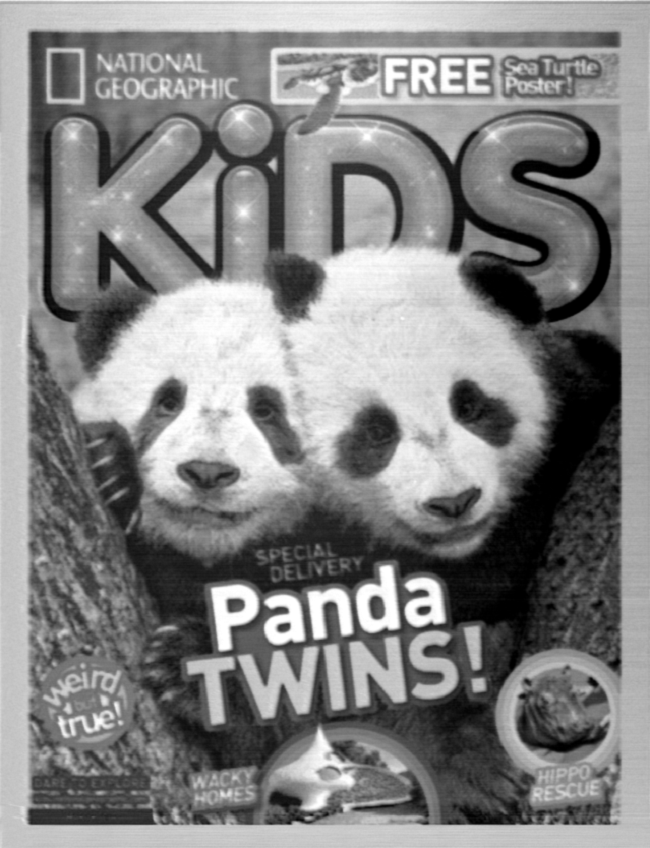

The team used the National Geographic Kids magazine as its testing model and readers were asked to vote for their favourite cover to be used for the project, which turned out to be that of a set of panda twins from the March 2014 issue.

The magazine cover used by the IBM team

Of course, the applications for such a device are much more far-reaching than making minuscule magazine covers. It is envisaged that this new capability may impact the prototyping of new transistor devices, including tunnelling field effect transistors, for more energy efficient and faster electronics for anything from smartphones to cloud data centres.

By the end of the year, IBM hopes to begin exploring the use of this technology in prototype transistor designs made of graphene-like materials.

“With our novel technique we can achieve very high resolution at 10 nanometres at greatly reduced cost and complexity,” said Dr Armin Knoll, a physicist and inventor at IBM Research.

“In particular, by controlling the amount of material evaporated, we can also produce 3D relief patterns at the unprecedented accuracy of merely one nanometre in a vertical direction. Now it’s up to the imagination of scientists and engineers to apply this technique to real-world challenges.”